The main purpose of processing and manufacturing is to get the main parts of the product, including the shell and structural parts.

The involved processes and elements are: preparation, mechanical processing, mold manufacturing, proofing, sampling, time management, production management, quality standards, quality control, cost control, the necessary support, process feedback, reproduction, duration, etc.

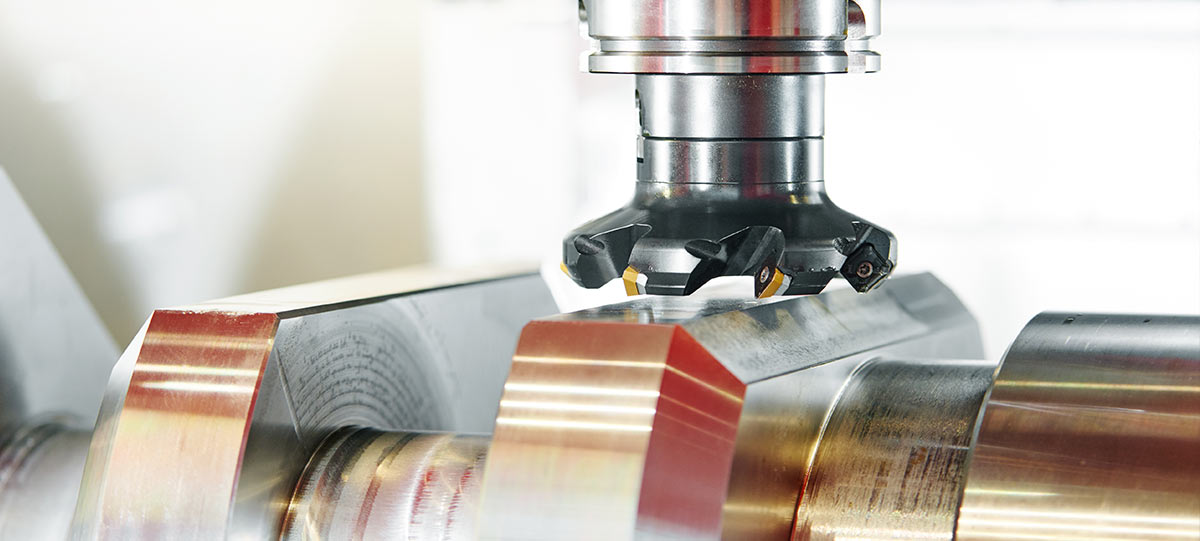

Mechanical processing refers to the process of changing the dimension or performance of the workpiece through a mechanical device. The process can be divided into cutting, casting, forging, stamping, extrusion, cutting and welding, etc.

Production types are usually divided into three categories by quantity:

1. Single production: single production of different structures and sizes of products, and rarely repeated.

2. Batch production: manufacturing the same products in batches in a year, with certain repeatability in the manufacturing process.

3. Mass production: the manufacture quantity of the product is very large, repeat the processing of a certain part of aprocess.

NOBLE's own core process is CNC machining, but Noble has a strong ability to integrate industry resources. It can provide you with almost all the processes that are needed for various types of parts manufacturing according to your needs. Compared to contact you directly to the corresponding manufacturer, Noble can provide the same level of price, but will provide a better service and ensure the delivery and quality. By choosing Noble, you can enjoy a convenient and guaranteed one-stop service. The company has CMM three-dimensional and other sophisticated high precision equipment, and can be good quality control according to your requirements and provide corresponding reports.

EN

EN  ES

ES PT

PT SV

SV DE

DE TR

TR FR

FR