Cancer Analyzer

Project Name:Cancer analyzer

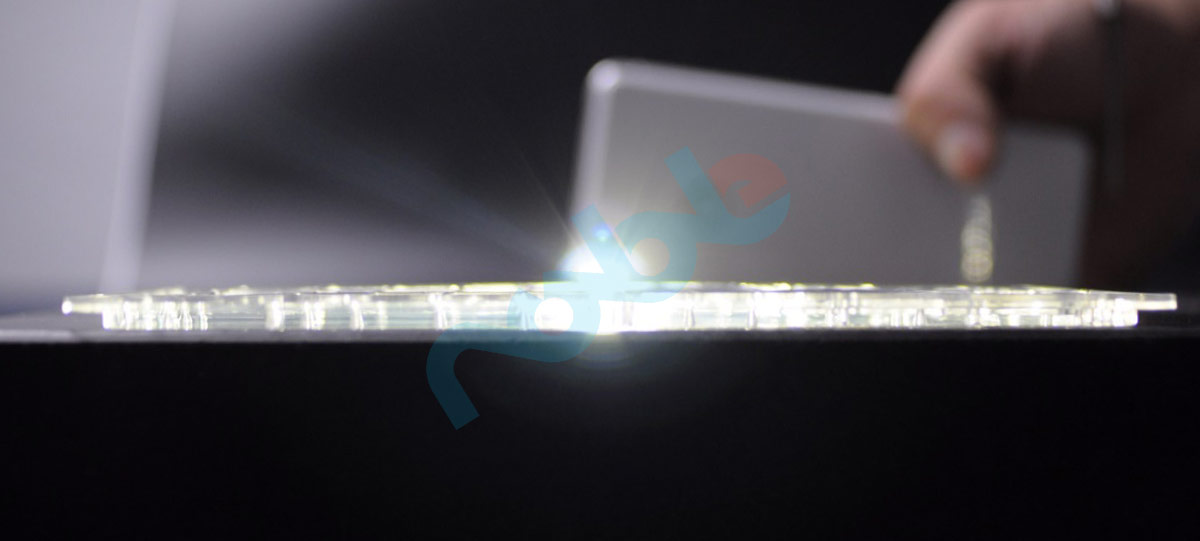

Product Usage : Used to detect cancer through blood more than 20 different cancers can be detected at the initial stage which can be discovered early treated as soon as possible reduce the cost of treatment and increase the chance of survival.

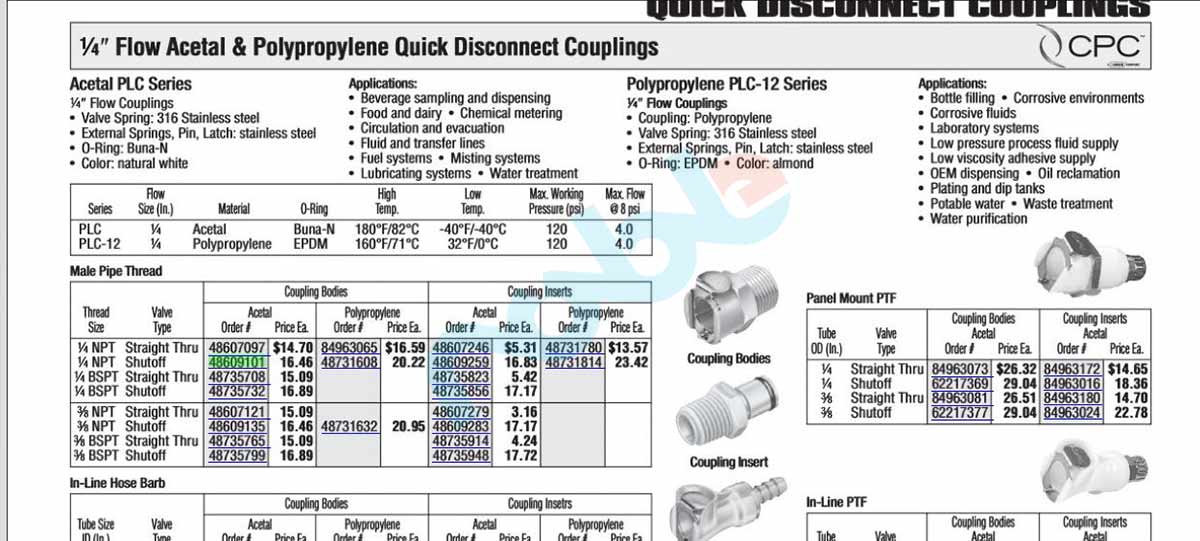

Customer Requirement : They hope we can provide all-round services such as structure optimization prototype manufacture molds injection molding parts purchase fixture design and manufacture assembly testing packaging ect.

Current Status : Small batch trial-produce and clinical testing to prepare for mass production.

Other Results : Innovation and breakthrough in some technical detail.

Used to detect cancer through blood more than 20 different cancers can be detected at the initial stage which can be discovered early treated as soon as possible reduce the cost of treatment and increase the chance of survival.

EN

EN  ES

ES PT

PT SV

SV DE

DE TR

TR FR

FR